- Additive manufacturing (3D printing) revolutionizes industrial design and prototyping with faster, cost-efficient production of complex parts.

- Automation & robotics increase production capacity, while IoT & big data improve resource management, predictive maintenance, and security.

- Augmented reality assists with machinery maintenance, safety warnings, training simulations, and warehouse operations.

- Technology has transformed industrial processes leading to more efficient, safe, and cost-effective operations.

- Industries must keep up with technological advancements to stay competitive in the market.

Technology has opened up new possibilities in all sectors of the economy. From how people communicate to how they transport goods, technology has made everything faster, safer, and more efficient.

In the industrial sector, technology has played an even more significant role. Thanks to technology, industrial processes are now quicker, safer, and less expensive. This blog will explore the critical role that technology has played in revolutionizing industrial processes.

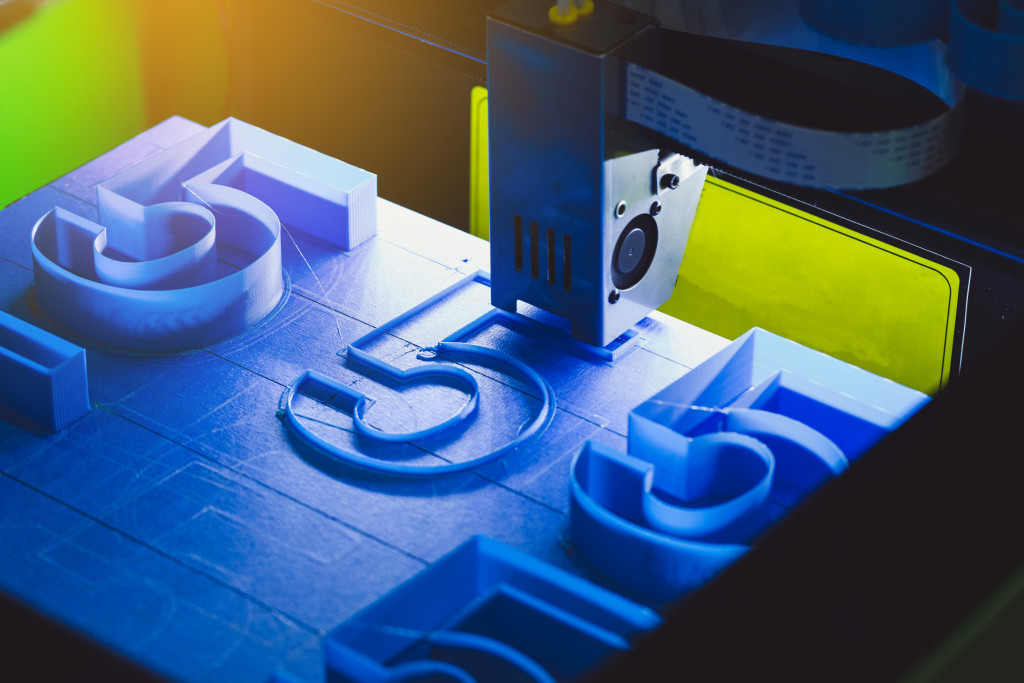

Additive Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized industrial design and prototyping. This technology has allowed industries to produce complex parts in small volumes faster and more cost-effectively than traditional manufacturing methods. 3D printing technology has also improved the safety and sustainability of industrial processes by reducing waste and improving recycling.

Different Industries

Today, additive manufacturing is utilized in many sectors, including aerospace, automotive, medical, and consumer products. In aerospace and automotive applications, 3D printing processes can replace manual machining operations with automated systems that produce parts faster and more precisely than ever.

Customize Consumer Products

Additionally, manufacturers use 3D printing to create customized consumer products such as jewelry and shoes. The medical industry has also benefited from 3D printing, as it can be used to create precision-engineered implants and prosthetics tailored to the patient’s needs.

Enhancing Mass Transfer and Separation Operations

Mass transfer and separation operations are essential to many industries, including pharmaceuticals, chemicals, petroleum refining, food production, biotechnology, and wastewater treatment.

Efficiency and Cost-Effectiveness

As such, these processes can benefit from improvements in efficiency and cost-effectiveness. This is where mass transfer enhancement solutions come into play. These technologies involve using various mediums to help increase the mass transfer rate and enable more efficient separations. These mediums can include structured materials, foam packing, energy-efficient filtration media, and inert gas spargers.

Separation Process

To enhance the efficiency of the separation process, you should install durable ceramic random packing into the distillation column. The material has a large surface area, creating intensive contact between the gas and liquid phases. This increases the rate of mass transfer, leading to more efficient separations. Additionally, as the material is inert and resistant to corrosion, it can be used in highly corrosive applications without risk of degradation or contamination.

Automation and Robotics

Automation and robotics have revolutionized the industrial sector. They have made it possible to automate many processes that were previously done by human workers, leading to more safety and accuracy.

Increased Production Capacity

Automated machines have also increased production capacity, thus allowing industries to produce more goods in less time. Robots can also work round the clock, increasing productivity and reliability. As robots and automated machines become more advanced, the possibilities for automation in the industrial sector become endless.

IoT and Big Data

The Internet of Things (IoT) and big data are changing how industrial processes are managed. IoT refers to connecting machines, sensors, and devices to the internet. Industrial IoT enables machines to share data, communicate with one another, and adapt to environmental changes.

Enhanced Operations

This results in better predictive maintenance, precise inventory management, and improved equipment optimization. Big data has helped industries better manage their resources by predicting maintenance needs, forecasting production supply and demand, and understanding customer trends.

Improved Security

IoT and big data have significantly improved security for industrial processes. IoT systems feature advanced authentication protocols that protect networks from malicious attacks. Additionally, predictive analytics helps to anticipate cybersecurity threats, allowing companies to take proactive measures against any possible attack.

Augmented Reality

Augmented reality (AR) has changed how industrial processes are managed and maintained. AR technology enables workers to view real-time information about machinery and equipment, making it easier to maintain, troubleshoot, and repair them on the spot.

Better Training

AR technology has also improved training and safety by giving workers interactive virtual training simulations and on-the-spot safety warnings. This helps keep employees safe and productive while reducing costly downtime.

Warehouse Operations

In warehouses, AR technology is also used to help with inventory management and order fulfillment. Providing real-time data about shipments makes the entire process more efficient and cost-effective. AR technology has become a powerful tool for industrial operations. It is paving the way for further innovation in the industry.

Technology has revolutionized industrial processes, resulting in more efficient, safe, and cost-effective operations. The article shows a few examples of how technology has transformed the industrial sector. As technology develops, industries can expect more innovation and advancements to help them achieve operational excellence while meeting the demands of a changing market. The industrial sector must continue to embrace technological advancements to stay competitive and meet the changing demands in the market.